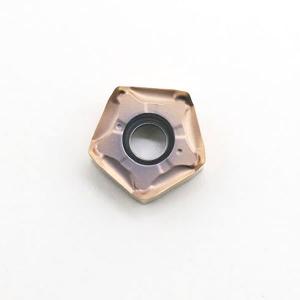

He design configurations of these carbide inserts comprise a body with replaceable cutting elements thus, known as indexable inserts.

Generally, the tool material must be harder than workpiece material to work on the workpiece.

The essence is to ensure the material can withstand thermal and mechanical loads as well as oxidation.

Moreover, the tool materials must meet the specific appropriate requirements of strength, hardness, thermal and oxidation resistance.

It helps in ensuring that the tool life acceptable within the required standards.

Ordinarily, we produce different types of various materials depending on the desired tool application.

Therefore, when selecting the ideal tool material, it is important to consider the specific intended use.

Carbide is the main material used for manufacturing carbide inserts.

However, there are a variety of tool material groups used for producing different carbide inserts.

Some of these materials include the following;

Cemented carbide

High-speed steel (HSS)

Cermet

Ceramics

Silicon nitride

Cubic boron nitride

polycrystalline diamond (PCD)

The main types of cemented carbide used to manufacture inserts include tungsten, titanium carbide.